- Ben Rich took over Skunk Works from legendary Kelly Johnson. Rich’s first big test was his confidence in stealth when those around him were doubtful of its potential

- Kelly deeply believed that an airplane that was beautiful would fly the same way

- Engineers had to live with their design through production. They were expected on the floor and couldn’t abdicate responsibility just because a design had been approved. Engineers spoke to designers who spoke to manufacturing who spoke to quality and then to flight testing. Quality reported directly to the CEO

- To save time, they built the plane vertically which allowed them to work in parallel rather than in series

- Advantageous Divergence

- 14 Skunk Works mantras

- The Skunk Works manager must be delegated practically complete control of his program in all aspects. He should report to a division president or higher.

- Strong but small project offices must be provided both by the military and industry.

- The number of people having any connection with the project must be restricted in an almost vicious manner. Use a small number of good people (10% to 25% compared to the so-called normal systems).

- A very simple drawing and drawing release system with great flexibility for making changes must be provided.

- There must be a minimum number of reports required, but important work must be recorded thoroughly.

- There must be a monthly cost review covering not only what has been spent and committed but also projected costs to the conclusion of the program.

- The contractor must be delegated and must assume more than normal responsibility to get good vendor bids for subcontract on the project. Commercial bid procedures are very often better than military ones.

- The inspection system as currently used by the Skunk Works, which has been approved by both the Air Force and Navy, meets the intent of existing military requirements and should be used on new projects. Push more basic inspection responsibility back to subcontractors and vendors. Don't duplicate so much inspection.

- The contractor must be delegated the authority to test his final product in flight. He can and must test it in the initial stages. If he doesn't, he rapidly loses his competency to design other vehicles.

- The specifications applying to the hardware must be agreed to well in advance of contracting. The Skunk Works practice of having a specification section stating clearly which important military specification items will not knowingly be complied with and reasons therefore is highly recommended.

- Funding a program must be timely so that the contractor doesn't have to keep running to the bank to support government projects.

- There must be mutual trust between the military project organization and the contractor, the very close cooperation and liaison on a day-to-day basis. This cuts down misunderstanding and correspondence to an absolute minimum.

- Access by outsiders to the project and its personnel must be strictly controlled by appropriate security measures.

- Because only a few people will be used in engineering and most other areas, ways must be provided to reward good performance by pay not based on the number of personnel supervised.

- There was a secret 15th rule - don't work with the navy

- There was so much secrecy around many of the skunk Works projects that inefficiency and obscurity was a feature not a bug. They had to fail their assembly locations plans and blueprints so well that it added in Normas friction and costs to their overall process

- There were of course technical and governmental problems but they succeeded and the stealth fighter became phenomenally profitable, making Lockheed billions of dollars

- No other manufacturer came close to building the intimate relationship between designer and user like skunk works did. They had the pilots responsible for flying the F1-17A part of the production process

- They developed homegrown talent that was able to get up the learning curve very quickly through proper training motivation and incentives

- Stealth plus precision missiles was a quantum leap in warfare rendering nearly useless billions of dollars spent on defense systems by the Russians and other enemies

- Kelly was of Swedish origin - "as stubborn as a Swede"

- The greatest compliment Kelly ever got was from a British colonel that said, “this old Swede can see the damn air!” That’s how efficient his designs were and how intuitive he was with aerodynamics and airplane design

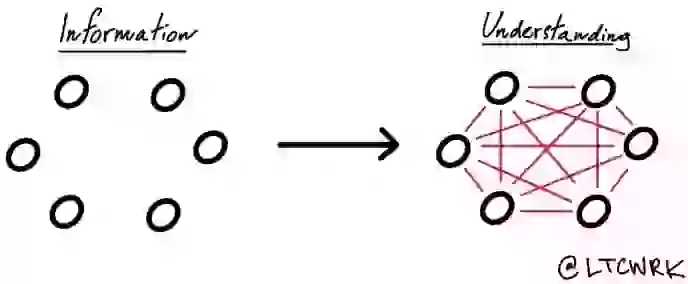

- Hologram in the Head

- Kelly believed that if he didn’t have the hell scared out of him as a test flight pilot at least once a year he wouldn’t have the proper perspective to design airplanes. He was one of the leading experts in nearly every aspect of the design and build of airplanes. Nothing ever got past him and he was frustrated by those who try to cover up their mistakes rather than own up to them

- One of Kelly‘s key mantras was to have everybody as close to the production floor as possible - even a stones throw away was too far as he wanted structural changes and questions to be addressed immediately. Any delays were to be reported to Kelly immediately and stock items were to be used in place of special parts, even at the expense of added weight - the potential for delay was too great if too many special parts were used

- Velocity

- Kelly was strong as an ox and challenged people to arm wrestling. He hardly ever lost

- The U2 spy plane was another great success and allowed the US to get reconnaissance data on the Soviet union without fear of being shot down. This was the greatest success and greatest bargain, allowing policy makers to know what they were truly up against

- The black bird may be the pinnacle of 20th century aviation and Kelly considered it his crowning achievement

- The SR 71 blackbird was the most advanced plane of the 20th century. However, they stopped building them in the 1970s and it was officially retired in 1990. The incredible thing is that the titanium skin and the speed at which it flew cause such he got the metal was annealed on every flight, making it stronger overtime

- A lot of the technology, planes, and ships that the Skunk Works built allowed for a much smaller team to have the same impact as a past larger team would have. However, in terms of an officer's prestige, ego, and future prospects, more and bigger was better so they had a hard time attracting ambitious and capable officers to these smaller yet more effective teams. Their stealth ship, Sea Shadow, fell into this category.

- An interesting paradox about stealth technology is that it is built to disappear, but it can’t be more quiet than the background noise or else they stand out just as much as if they were using no stealth at all

- They were two people set to potentially take over for Kelly when he retired. Ben was Kelly’s favorite since he was technically great but more importantly a good leader straightforward and someone who had big ideas and big vision. There are many great engineers but a few good leaders

- Alloying

- Don’t build anything you don’t believe in

- Skunk Works would likely not be able to exist without a parent organization who they could push and pull talent from. This helps keep the team streamlined and focused without growing excessively large and bureaucratic

- Another important skunk works mantra is to stick with suppliers who perform well. Switching suppliers just because of cost eats up expenses in different ways and is almost never worth it. Form long lasting relationships with good suppliers

What I got out of it

- Exciting book to get behind the scenes of one of the most innovative and important aerospace groups of the past 50 years. A lot to learn from in terms of leadership, velocity, and management organization